Capabilities

Tooling

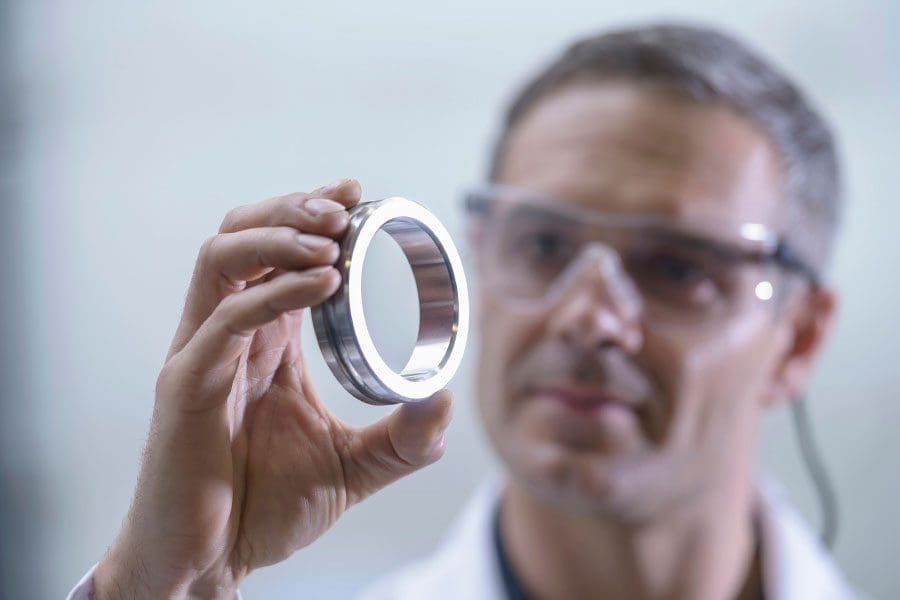

Precision Metal Tooling, Prototyping & Short Runs

Crafting High-Quality Innovations with Shortened Lead Times

Our state-of-the-art, multi-million dollar tooling facility is uniquely positioned to craft dies, fixtures, gauges, and specialized machinery essential for manufacturing a diverse range of metal products with precision.

Prototypes & Short Runs

In-house design and tooling, coupled with cutting-edge laser cutting and Wire EDM equipment, constitute the perfect blend for handling prototypes and short runs.

In-house design and tooling capabilities, complemented by advanced laser cutting and Wire EDM equipment, enable us to produce prototypes and manage short runs. Backed by our Total Quality Management (TQM) process, we deliver short-run stampings to the most rigid specifications and highest quality standards.

Short Run Special Tooling Capabilities

- Our inventory includes tooling capable of accommodating up to 6” outer diameter (O.D.).

- We can punch materials ranging from 0.001 to 0.125 inches thick, both solid and laminated.

- Unique short-run, low-cost tooling design.

- CNC Amada Turret punch presses.

- Extensive bending and forming capabilities allow for versatile production.

- Our highly trained operators possess the skills to perform to exacting tolerances.

- Laser Cutting & Wire EDM technologies further enhance our precision.